What is knife gate vavle

Ensure optimized and environmentally responsible operations with knife gate valves designed for general, severe, and critical applications

What is a knife gate valve?

Knife gate valves are similar in design to gate valves and were initially developed for use in the pulp and paper industry. As the name implies, these valves can cut through thick, porous media that may contain a high concentration of suspended solids (such as dense, sewage sludge) which had caused problems with valves not seating completely and thus leaking.

Where are knife gate valves used?

Knife gate valves are designed mainly for on-off and isolation services in systems with high content of suspended solids. Knife gate valves are especially beneficial for handling slurry in addition to viscous, corrosive and abrasive media. The valves have a minimised pressure drop in fully open position, they are easy to actuate, they have a relatively low weight and are cost-effective.

Knife gate valves are similar in design to gate valves and were initially developed for use in the pulp and paper industry. As the name implies, these valves can cut through thick, porous media that may contain a high concentration of suspended solids (such as dense, sewage sludge) which had caused problems with valves not seating completely and thus leaking.

A knife gate valve works by lifting a plate with a planar or “knife” edge from the path of flow that can literally cut through various impediments during closing thereby creating complete closure against a soft sealing surface. This soft sealing surface generally dictates use in rather low-pressure systems and is not designed to handle high pressure. Both gate and knife gate valves are primarily designed for isolation or on/off service rather than a throttled or partial-flow application.

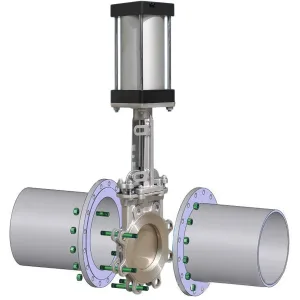

Design & parts of a knife gate valve

Knife gate valves are a specific type of isolation valve that is typically used for media that are not hazardous such as wastewater. The bore of a knife gate valve is full and smooth so the use of a cleaning pig for maintenance is possible. While there is no pressure loss across the valve, they are susceptible to “chatter” or vibration during opening or closing caused by fluid flow against the gate. This is not a significant issue as the appropriate application for a knife gate valve is isolation, not flow restriction, so the normal operating position is fully open or fully closed. A thin (typically) stainless-steel gate is raised and lowered into the bore by a spindle or rising screw and, unlike other gate valves, lifts outside of the valve body when raised. The guide and seal are located around the circumference of the bore and provide a bi-directional, bubble-tight seal.

Knife gate valves are similar in design to gate valves and were initially developed for use in the pulp and paper industry. As the name implies, these valves can cut through thick, porous media that may contain a high concentration of suspended solids (such as dense, sewage sludge) which had caused problems with valves not seating completely and thus leaking.

- Knife gate valves are a specific type of isolation valve typically used for non-hazardous media like wastewater.

- The valve has a full and smooth bore, allowing for the use of a cleaning pig during maintenance.

- There is no pressure loss across the valve when it is fully open.

- However, they may experience “chatter” or vibration during opening or closing due to fluid flow against the gate, but this is not a major concern as they are primarily used for isolation rather than flow restriction.

- The normal operating positions for a knife gate valve are fully open or fully closed.

- A thin, typically stainless-steel gate is raised and lowered into the bore by a spindle or rising screw.

- Unlike other gate valves, when raised, the gate lifts outside of the valve body.

- The guide and seal are located around the circumference of the bore, providing a bi-directional, bubble-tight seal.

Knife gate valves are available with bodies made of cast iron, cast steel, stainless steel, fabricated steel, or exotic alloys depending on the specific application. While the gate is usually made of stainless steel, the yoke can be of similar materials to the valve bodies and may include a brass or bronze bearing. The seat seals can be elastomers or flexible metal. Reference the diagrams below to identify the different parts that are common. Bore sizes from DN 50 to DN 600 are common with knife valve dimensions of DN 1000+ being available.

Both types can be used in applications involving:

- Slurries

- Heavy oils

- Non-flammable viscous fluids

- Wastewater

- Clean water

Working theory of knife gate valves

All valves are designed to limit or stop the movement of a liquid in a flow stream but there is a myriad of designs and applications that depend on the specific use case. Therefore, there is a slight difference between a gate valve and a knife gate valve in construction. In a typical wedge gate valve, as the name implies, the wedge serves as a “gate” to move into the flow stream and seal off or reduce the flow by impeding the path. A knife gate valve is a specific design of a valve that uses a knife edge that can enter the flow stream and, if necessary, use the edge of the gate to separate any materials that might prevent the valve from sealing completely.

As described above, the knife gate can be raised using a spindle or a rising screw and the actuating mechanism can be manual or pneumatic/electrically activated. The open/closed state of the valve can be observed from the position of the gate – if it is visible above the valve body then it is open and likewise, if it is not visible then the valve is closed.

Advantages of a knife gate valve

Knife gate valves are a specific type of isolation valve that is typically used for media that are not hazardous such as wastewater. The bore of a knife gate valve is full and smooth so the use of a cleaning pig for maintenance is possible. While there is no pressure loss across the valve, they are susceptible to “chatter” or vibration during opening or closing caused by fluid flow against the gate. This is not a significant issue as the appropriate application for a knife gate valve is isolation, not flow restriction, so the normal operating position is fully open or fully closed. A thin (typically) stainless-steel gate is raised and lowered into the bore by a spindle or rising screw and, unlike other gate valves, lifts outside of the valve body when raised. The guide and seal are located around the circumference of the bore and provide a bi-directional, bubble-tight seal.

Knife gate valves are similar in design to gate valves and were initially developed for use in the pulp and paper industry. As the name implies, these valves can cut through thick, porous media that may contain a high concentration of suspended solids (such as dense, sewage sludge) which had caused problems with valves not seating completely and thus leaking.

- Knife gate valves are a specific type of isolation valve typically used for non-hazardous media like wastewater.

- The valve has a full and smooth bore, allowing for the use of a cleaning pig during maintenance.

- There is no pressure loss across the valve when it is fully open.

- However, they may experience “chatter” or vibration during opening or closing due to fluid flow against the gate, but this is not a major concern as they are primarily used for isolation rather than flow restriction.

- The normal operating positions for a knife gate valve are fully open or fully closed.

- A thin, typically stainless-steel gate is raised and lowered into the bore by a spindle or rising screw.

- Unlike other gate valves, when raised, the gate lifts outside of the valve body.

- The guide and seal are located around the circumference of the bore, providing a bi-directional, bubble-tight seal.

Knife gate valves are typically found in wastewater treatment plants, chemical plants, mining, cement plants as well as in many other industrial applications while gate valves are typically found in drinking water mains, distribution networks and drinking water pump stations.

Learn More Information About Control Valves

Contact Us

TelePhone

86 13729936450

Location

Building C,Longchang Micro Chuangyuan,N0.26 Hantang Street,Dongcheng District,Dongguan,City,China